Prototyping

ICPS Prototyping

You need a prototype.Show us your project. We will realise it.

We will realize your project from your ideas!

You will receive a high-quality prototype, faithful to the plastic injection at the end of the process.

We will realize your project from your ideas!

You will receive a high-quality prototype, faithful to the plastic injection at the end of the process.

3D PRINTING

- Three stereolithography 3D printers,

- One printer capable of printing technical materials such as: TPU, PEEK, PEI (also called ULTEM), carbonfibre, graphite, Kevlar, FPE, polycarbonate, fibreglass, POM (also called DELRIN), PolyVyniliDene Fluoride (PVDF),

- One Polyjet,

- One selective laser sintering machine which allows the printing of polyamides and TPUs

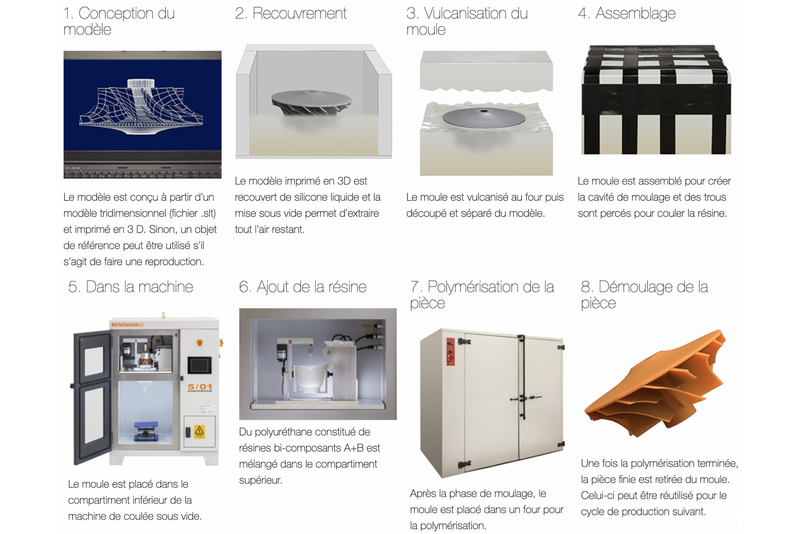

VACUUM CASTING

Our production line for the vacuum casting allows us to manufacture small and medium-sized parts in a material that simulates polymer injection.

- Using a master model, we create a silicone mold. Then, we make castings in numerous materials, standard and technical, such as: PEHD / PP / PS / ABS / ABS-PC / PA / PC transparents.

- On demand, we manufacture parts in different reinforced materials such as: metallic powder, fiberglass, mica, ceramics, and others according to your needs.

Equipment used for rapid prototyping

3D Scanner

We use a 3D scanner to effectuate reverse engineering projects, with speed and precision.

Special-purpose Machines

After the design phase, we also create special machines in our atelier. These single-copy machines respond to the specific needs of an industrial firm.

Paint Booth

We use our Paint Booth to put finishing touches on our manufactured parts: sanding, coating (varnish or lacquer), and soft-touch varnish.

Machining

We offer machining operations with milling machines and lathe machine available to us through our local partners. We also do sheet-metal work and laser cutting in short delays.

Why prototyping ?

- Functional and mechanical validation of a part, during the design phase of its manufacturing.

- Testing of parts in real conditions, because the prototype is practically identical to the part.

- Mechanical, esthetic, or ergonomic validations in very short delays.

- Market-launch time of the product reduced to a few weeks.

- Manufacture of parts and assemblies without assembly (or monobloc assembly).

- Elimination of manufacturing errors by direct and exclusive exploitation of the 3D file.

- Manufacture of small series of plastic parts for pre-production, their distribution, or their promotion.

- Use of prototypes for the production of technical catalogs and presentation models.